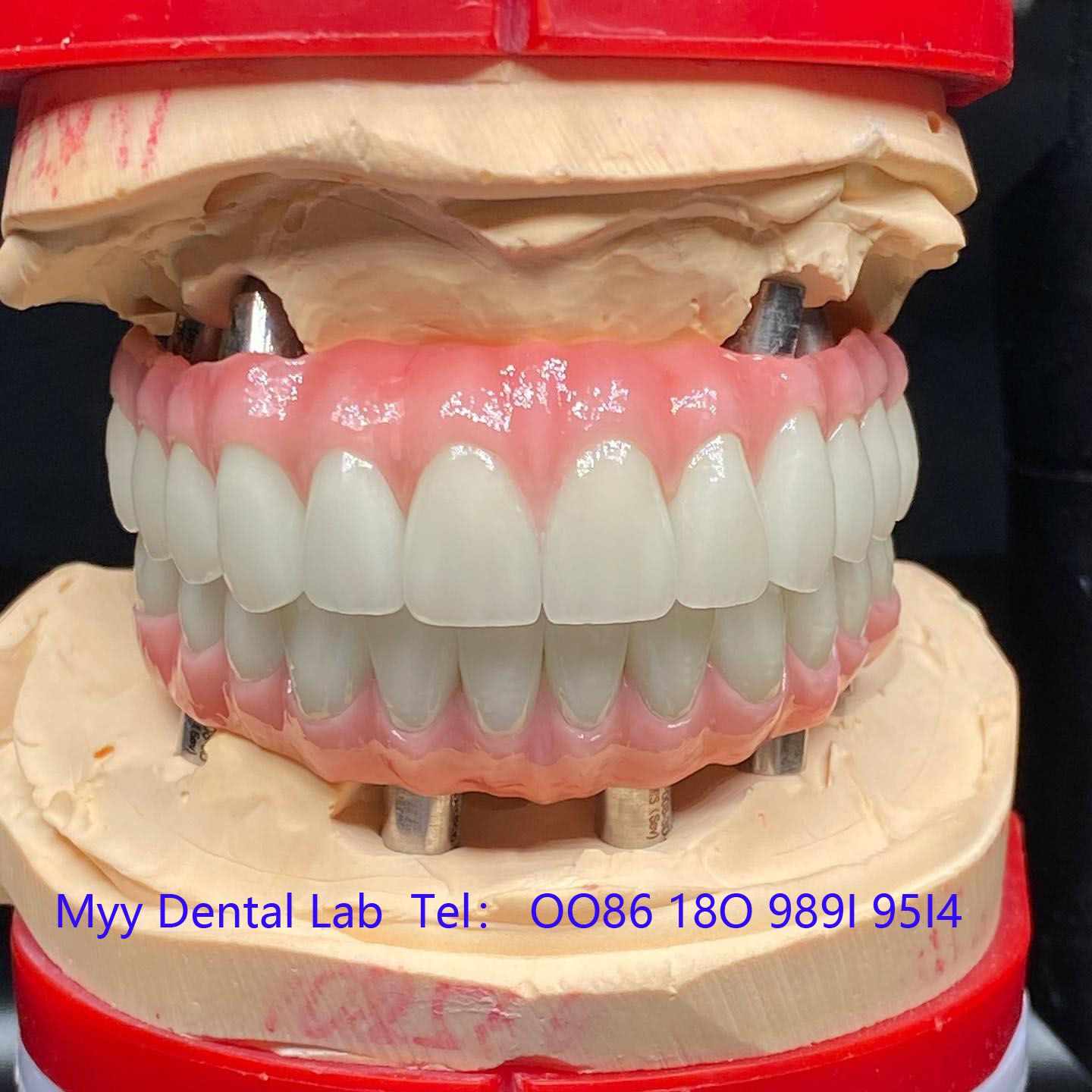

Myy Dental Laboratory is an ISO and FDA certificated high quality China dental lab in Shenzhen. With a floor area of 5000 square meters .

Its quality consistency, fast turnaround time, good materials and professional communications have won excellent feedbacks from European, USA and Australian markets. In addition to its traditional working process, it works also digitally.

How can a China dental lab cut the cost so low while maintaining high quality?

A China dental lab can achieve low costs while maintaining high quality mainly relying on mature industrial chain support, scale effect, and efficient localized operations, rather than compromising quality. Below are the core reasons:

- Complete Localized Industrial Chain: China has a well-developed supply chain for dental materials (e.g., zirconia blocks, resin) and equipment (CAD/CAM systems). Local procurement eliminates import tariffs, transportation costs, and long lead times, significantly reducing raw material and equipment costs. Many domestic suppliers also meet international quality standards (e.g., ISO), ensuring material quality while lowering prices.

- Economies of Scale: Most China dental labs focus on bulk production (serving global dentists, clinics, or distributors). Large order volumes allow them to spread fixed costs (e.g., equipment depreciation, R&D, management) across more products, reducing the unit cost of each restoration (crown, bridge, etc.).

- Cost-Effective Professional Labor: Compared to欧美 (Europe and the US), China has a larger pool of well-trained dental technicians (with specialized education in digital dentistry) and lower labor costs. Labs can maintain high production efficiency (e.g., 24-hour shift workflows for urgent orders) without excessive labor expenses, while strict training and quality control ensure technician skills meet international standards.

- Efficient Digital Workflows: China dental labs widely adopt mature CAD/CAM technology (e.g., imported or domestic high-precision scanners and milling machines). Automated design and production reduce manual errors, cut material waste (e.g., precise material cutting based on digital models), and speed up turnaround—all of which lower rework rates and operational costs while guaranteeing consistent quality.

- Policy and Regional Advantages: Some regions in China (e.g., manufacturing hubs) offer preferential policies for export-oriented medical device enterprises (e.g., tax rebates, industrial park subsidies), further reducing operational costs. Meanwhile, proximity to major global shipping ports (e.g., Shanghai, Shenzhen) lowers international logistics costs for overseas clients.

Write a comment ...